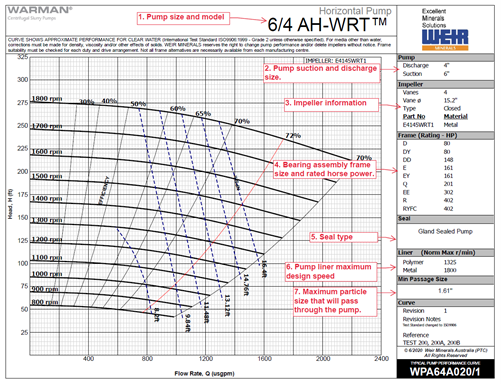

Weir Minerals provides a wealth of information on Warman pump curves. Warman pump curves can be difficult to navigate if you are not familiar with them. All of the Warman pump curves are laid out the same.

Information and the location of the information on a Warman pump curve can be seen on the included images, and is described below.

- Located at the top is the pump size and model: In the example we are using a Warman 6×4 pump, model AH and WRT design. WRT stands for wear reduction technology.

- In the upper right-hand corner is the pump suction and discharge size. The size refers to the pump suction and discharge inside diameter.

- The impeller information is located below the suction and discharge information. You will find the number of vanes, impeller diameter, impeller type, part number and material. In the example below, the impeller has 4 vanes with a 15.2” diameter. The impeller is a closed design versus an open design and is metal (high chrome iron).

- Below the impeller information on the right hand side is information on the available bearing assemblies for that Warman pump size and model. For example: A Warman 6×4 EAH pump has a “E” size bearing assembly which is designed for a maximum installed horse power of 161.

- The next item is the seal type. The example curve has a pump with a standard packed gland. Warman pumps are available with many different seal arrangements. The most common are packed, expeller, and mechanical seal.

Liner material maximum design speed. The maximum design speed is based on the material point of failure. Weir Minerals does not recommend exceeding the design speeds.

Liner material maximum design speed. The maximum design speed is based on the material point of failure. Weir Minerals does not recommend exceeding the design speeds.- Minimum passage size. The description is a little misleading. You have to look at it from the pump’s point of view. This is referring to the smallest internal pump dimension. The example below the smallest internal dimension for a 6×4 AH pump with a E4145WRT1 impeller is 1.61”

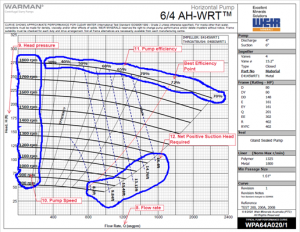

- The flow rate is located at the bottom of the page. The units are gallon per minute.

- The head is located on the left side of the page. The units are in feet of head.

- The pump speed is located on the left side of the page. Slurry pump curves are different from ANSI pump curves. ANSI pump curves normally have a set speed and vary the impeller diameter. Slurry pump curves have a set impeller diameter and vary the pump speed.

- Pump efficiency is located at the top of the curve. The red efficiency line is known as best efficiency point or BEP. The Warman 6×4 AH example curve has BEP of 72%.

- NPSHr or net positive suction head is located towards the bottom of the curve. We recommend that NPSHr be at least 2 ft higher than NPSHa, otherwise the pump will cavitate.

If you need help sizing a Warman slurry please give Jasper Engineering a call.

Ready to learn more? – contact Jasper Engineering today at (218) 262-3421 or (906) 485-6361, or email us at [email protected].